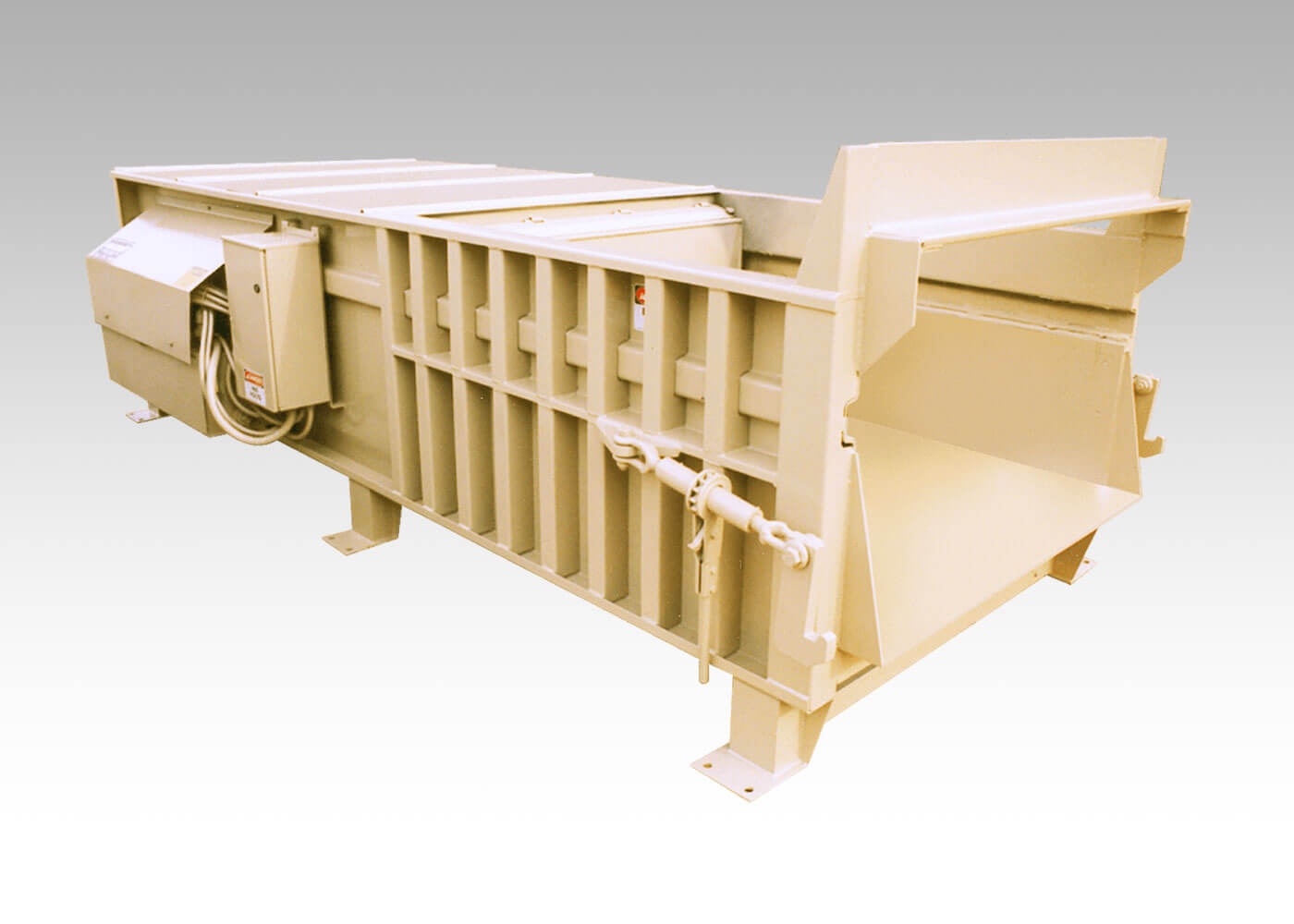

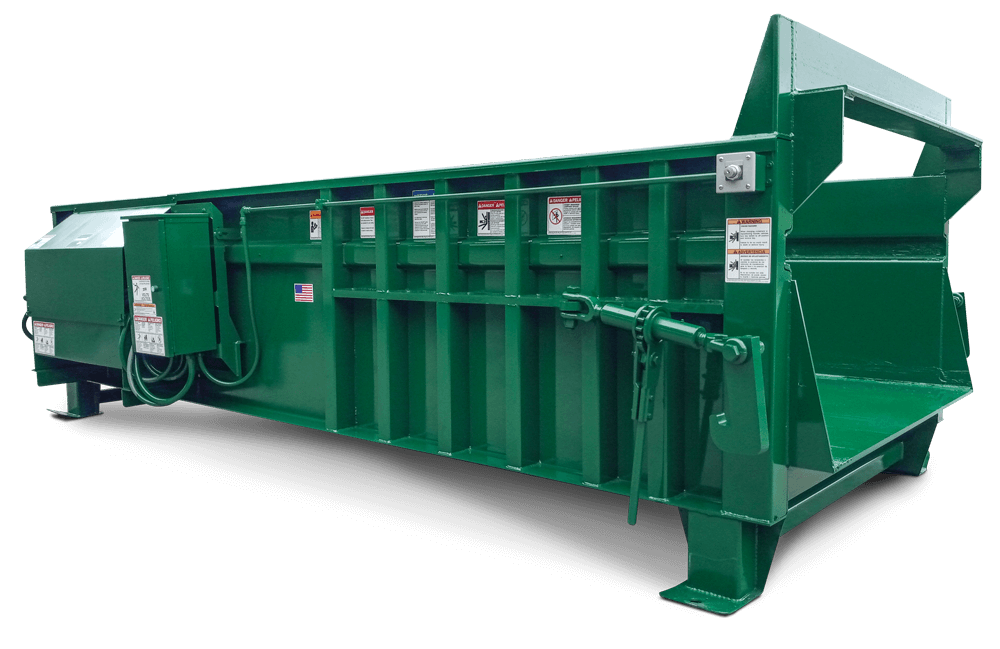

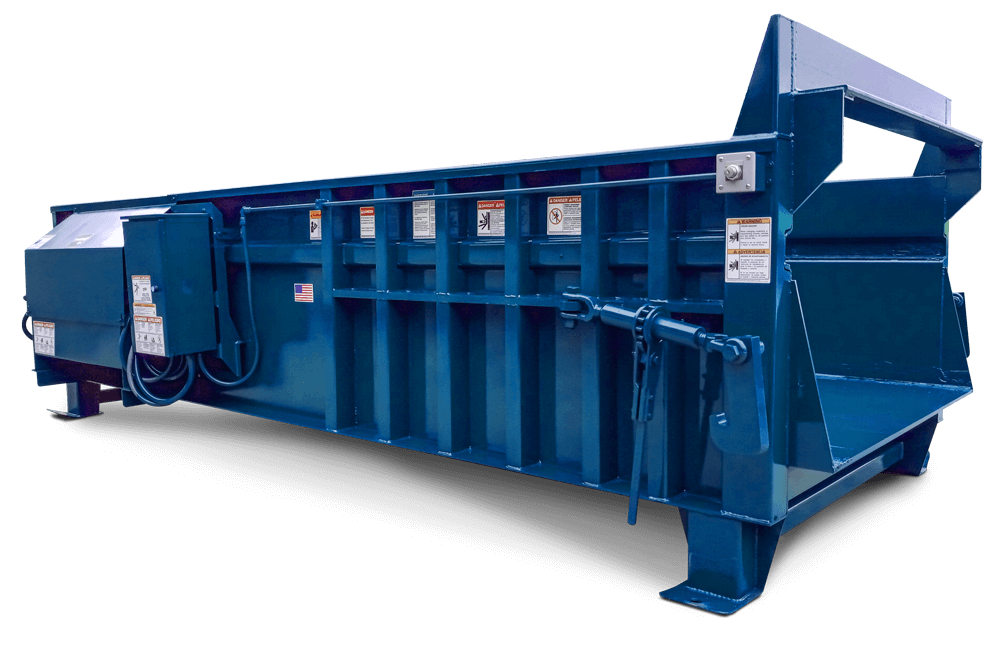

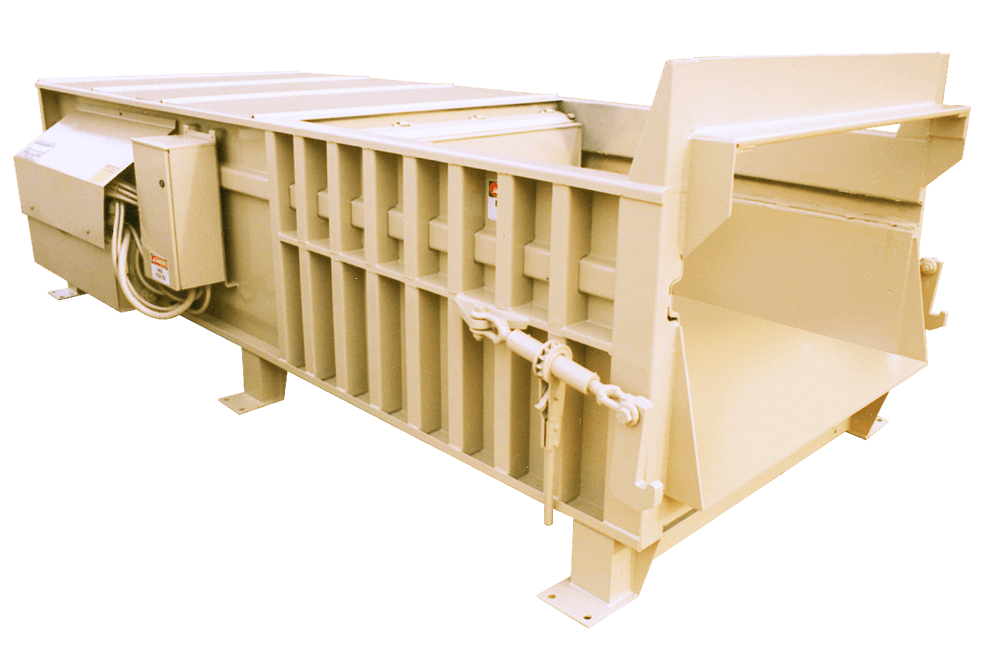

RJ-325 & rj-325hd Stationary Compactors

The Marathon® RamJet® RJ-325 series stationary trash compactor is a proven workhorse with excellent capability, ensuring top performance in heavy commercial and industrial applications. The RJ-325 is unique to other compactors in its class, providing a large 60″ wide by 67 1/2″ clear-top opening, and a 33″ deep charge box – a feature for peak loading times or when compacting bulky items.

Marathon brand components are selected for longevity and minimum maintenance, with special attention given to the selection of high-duty-cycle components. Stress engineering provides the optimum degree of structural integrity. Only the best materials are used and the highest standards of quality are observed in the manufacturing process.

Have Questions About The RJ-325 Series Trash Compactor?

Contact your local Marathon Compaction team today to request a complimentary site survey.

3 Yr. Structure | 2 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Compaction Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. Our existing Signature Series® Warranty, Compactor Warranty, and Auger Warranties have been combined into a new Compaction Solutions Warranty. The Compaction Solutions Warranty includes 3-year structural warranty, 2-year part warranty, and 1-year labor warranty.The RJ-325 Series Compactor

The Marathon RamJet RJ-325 series is a proven workhorse with excellent capability, ensuring top performance in heavy commercial and industrial applications. The RJ-325 is unique to other compactors in its class, providing a large 60″ wide by 67 1/2″ clear-top opening, and a 33″ deep charge box – a feature for peak loading times or when compacting bulky items

Engineered for Durability

The RJ-325 is stress-engineered for durability, adding strength where it belongs. The 1/2″ charge box floor is reinforced with seven heavy-duty steel channels, the 1/2″ steel plate ram face is backed with 10″ structural channels and extra-rugged reinforced sides.

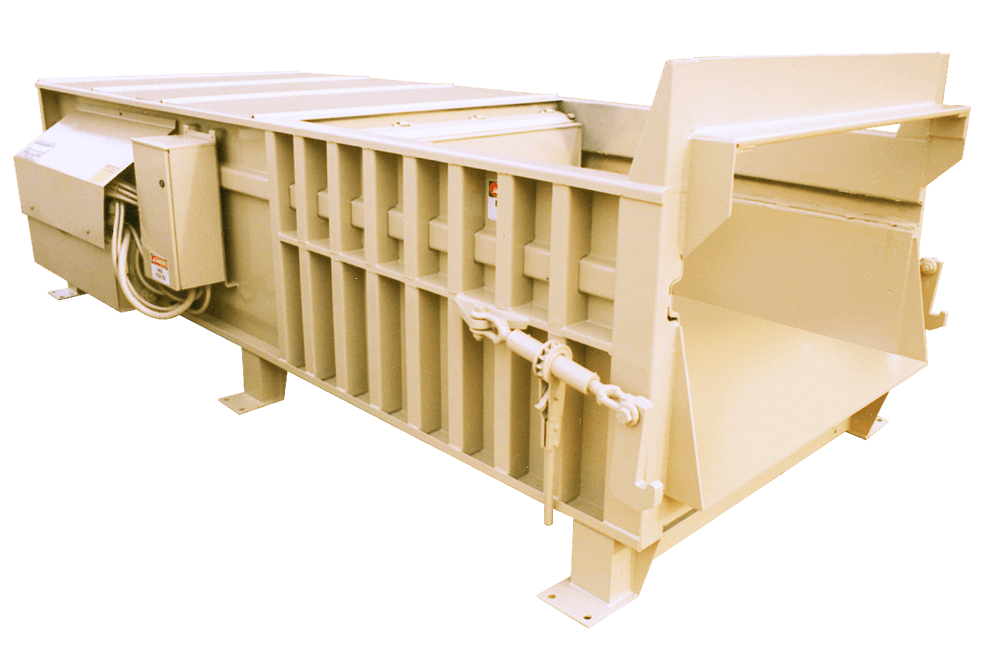

The RJ-325HD Compactor

The large 59 1/2″ wide by 67 1/2″ long clear-top opening and superior strength of the RJ-325HD make it just right for large volumes of crates, skids, and other hard-to-compact industrial refuse and trash. Waste is crushed to a fraction of the original bulk.

Heavy-Duty Design

The Marathon RJ-325HD is engineered with extra steel to meet the demands of heavy-duty industrial use. Cylinder supports, a 1″ thick breaker bar, a 3/8″ ram top, and extra side supports are added for superior endurance. Also standard on the RJ-325HD are 1/4″ thick steel charge box liners and a 1/2″ thick abrasion-resistant steel plate on the charge box floor.

RJ-325 & RJ-325HD Features & Benefits

- Designed to handle heavy-duty waste streams.

- Ideal for municipal drop-off centers.

- Heavy-duty design and high compaction force yield excellent volume reduction with MSW.

- User-friendly 48″ deck height offers a standard deck height while maintaining the same clear-top opening as a 4-yard compactor.

RJ-325 Stationary Compactor Features

This provides the convenience and ease-of-maintenance of a remote power pack with the space savings of an integrated power unit.

The packing ram is supported by specially formulated cast iron shoes which ride on replaceable wear strips. This exclusive design protects the charge box floor from the full force of the packing ram, extending its life and dramatically reducing compaction robbing friction.

Simplified three-button control system. It is key-operated, fully automatic, and contained in a weatherproof NEMA 4 enclosure. Connected to the power pack with 13′ of conduit, the controls can be mounted in your choice of location for operator convenience.

Marathon stationary trash compactors can be fitted with a variety of material handling equipment such as chutes, hoppers, and dumpers. The compactor shown is fitted with a side-fed hopper and a ground level dumper. Cart dumpers can be custom built to your specifications to accommodate existing cart systems.

AVAILABLE WITH BAYNE THINLINE CART LIFTER

Equipped with an integral cart lifter, the RJ-325 offers an economical and safety-conscious solution for a wide variety of waste material handling applications.

Bayne® Thinline® cart lifters work with standard two-bar roll-out carts and can lift up to 750 lbs. Lifters have a durable, powder-coated finish that can stand up to the elements.

PERFECT FOR TIPPER-SYSTEM APPLICATIONS

The RJ-325 is the perfect choice for applications requiring a tipper system. These tippers can extend the benefits of compaction to all areas of operation while keeping equipment investments to a minimum. Carts or containers can be located at individual waste generation sites within the operation, and then emptied into the compactor with the cart-tipper option.

Compaction Options

The perfect configuration for your specific needs

Options are an essential part of virtually any compactor installation. Whether the options are for safety issues, convenience, operation efficiencies, or monitoring systems, waste-handling equipment can be fitted with a variety of customizable features to meet the demands of the application. Marathon compactor options include several categories such as: container-fullness measuring systems, usage-measurement systems, cycle-control systems, power pack options, odor-control systems, and steel options.

View Compactor Options