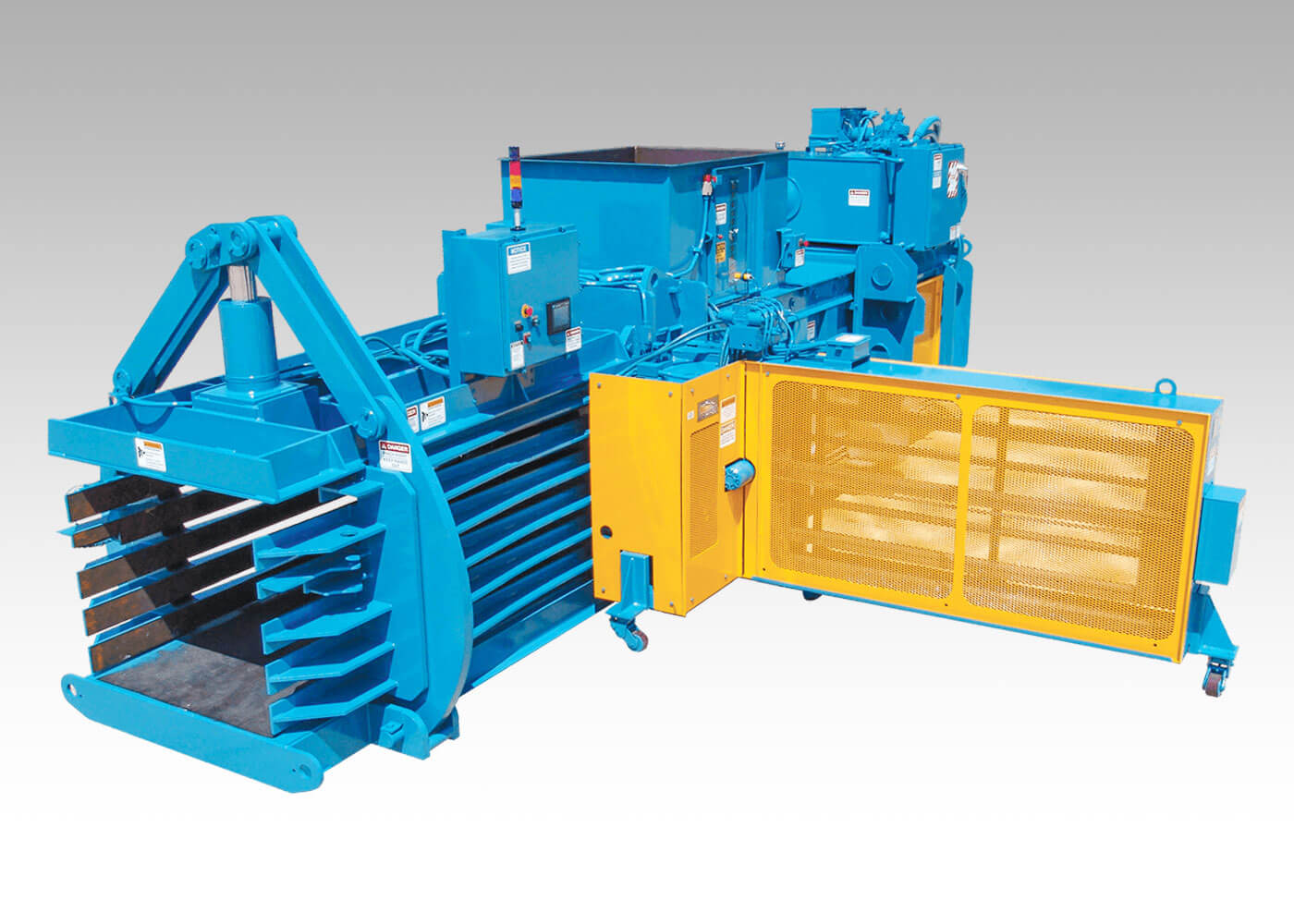

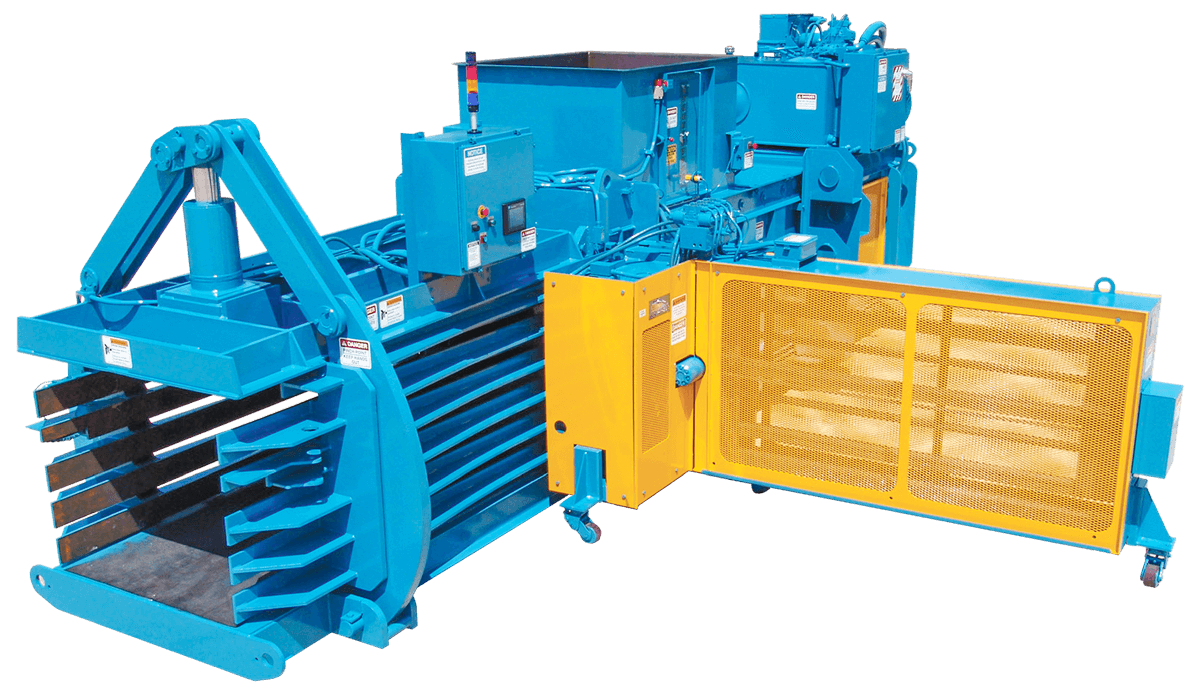

TIEger Auto-Tie Horizontal Recycling Balers

Highly Efficient and Precision-Built

Marathon® TIEger® auto-tie horizontal recycling balers use highly efficient gear twisters, eliminating bale wire pigtails. This feature of the Tieger auto-tie baler results in more than a 10% reduction in wire consumption and related costs. TIEger auto-tie baler ear twisters and inserter needles are hydraulically driven and baling wire is dispensed directly from our unique box holders. Hydraulic wire positioners precisely align the wires for pick-up by the inserter needles, making the TIEger recycling baler one of the most reliable auto-tie horizontal balers on the market.

Marathon auto-tie recycling balers are designed for high-productivity and ease of use with advanced electronics, such as the programmable PLC controller and color touch-screen operator interface. From this interface, the operator can control a variety of baler functions such as auto and manual modes, bale settings, system pressure, bale length, and perform computerized diagnostics. The main panel box features IEC controls.

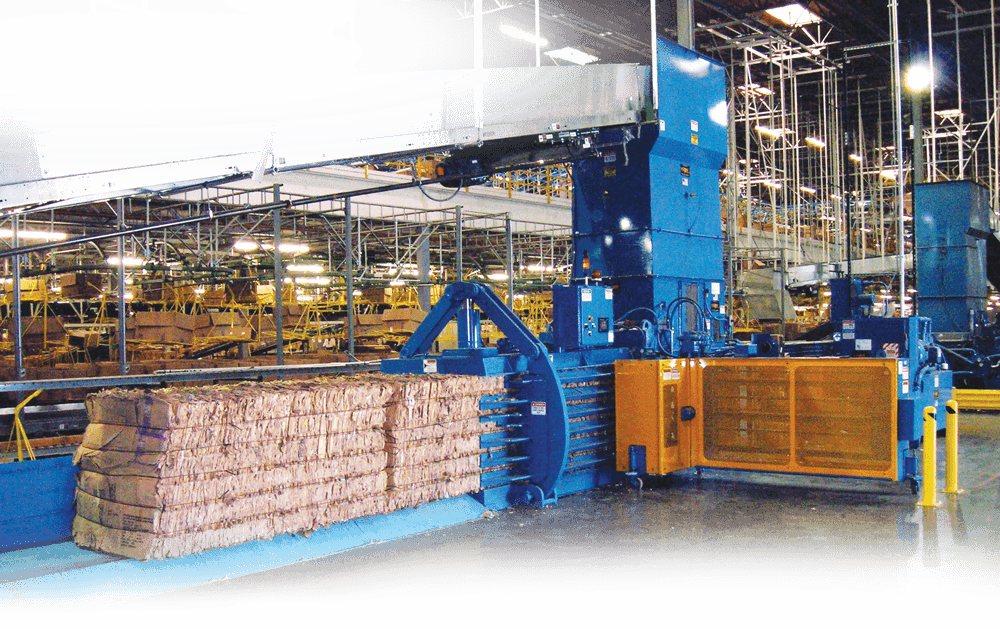

If you are looking for the best auto-tie balers on the market, Marathon Tieger balers provide the ultimate in efficiency, reliability, and value to recycling centers and MRF facilities. To learn more about Marathon Equipment’s line of Auto-Tie Balers, contact your local representative today for a free site survey. We’ll gladly provide you with a free analysis of your specific site needs and recommend the best auto-tie baler system for your application.

Have Questions About TIEGER AUTO-TIE Recycling BALERS?

Contact your local Marathon Recycling Compaction team today to request a complimentary site survey.

5 Yr. Structure | 1 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Transfer Compaction & Recycling Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. The existing Marathon Recycling Solutions Warranty has also been updated to include Transfer Compactors. The Transfer Compactor and Recycling Solutions Warranty include 5-years structural warranty, 1-years part warranty, and 1-year labor warranty.TIEger Auto-Tie Baler Features & Benefits

- Tieger auto-tie balers feature replaceable serrated body and ram shear blades

- Tieger auto-tie balers are equipped with single-cylinder bale tensioning system

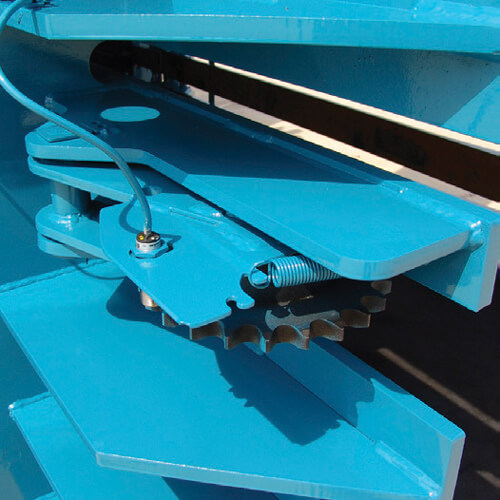

- Tieger auto-tie balers have spring-loaded retainer locks, adjustable wire positioners, and adjustable inserter needle positioners

TIEger Auto-Tie Baler Structural and Mechanical Features

- Single-cylinder tension system, which leverages and generates force on all four sides

- All pivot points have solid-steel bushings and grease fittings

- Adjustable inserter needle positioners (on the side opposite the tie) maintain correct needle position

- Inserter and twister assembly cabinet pivots for easy access and maintenance

- Inserters and gear twisters are driven by hydraulic motors

- Hydraulic wire positioners for precision alignment

- Bolt-in shear blades are replaceable (Only available on Narrow Shear, Wide Shear, and Extra Wide Shear models)

- 500 Brinell steel wear liners on the floor and ram bottom

- Chute-type feed hopper with access door equipped with viewing windows on both sides of the baler

- Several hopper styles to choose from, such as hand-feed, or chute-feed, as well as various types of conveyor in-feed systems

- Oversized ram hold-down bars are adjustable from the exterior of the machine

- Heavy-duty, spring-loaded retainer locks to prevent material spring-back into the charge box

- Baling wire box holders make loading quick and easy with no adjustment required. Ceramic wire guides and adjustable wire rollers

- Optional wire run-out sensor notifies operators of the need to swap out baling wire

Single-cylinder bale tensioning system with linkage bars provides up to one million pounds of extrusion force.

Spring-loaded retainer locks, adjustable wire positioners, and adjustable inserter needle positioners.

Spring-loaded counter wheel, located on the side of the baler, sends a digital reading to the operator interface.

In-feed hopper has viewing windows on both sides & hopper door. Infrared photoelectric sensors are adjustable to height of hopper door window.

TIEger Auto-Tie Baler Electrical and Hydraulic Features

- Spring-loaded counter wheel located on the side of the baler sends digital bale length reading to the operator interface

- Color touch-screen operator interface with programmable logic controller provides many functions such as diagnostics, bale set-up, bale length, and system pressure

- Infrared photoelectric sensors are adjustable to the entire height of the hopper door window

- ANSI compliant start-up alarm and beacon

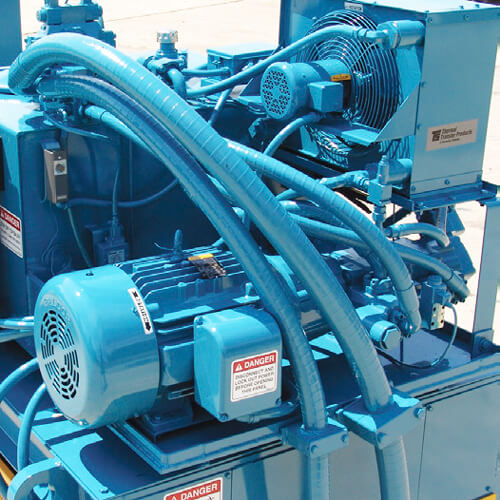

- 460V/3-phase/60Hz high-efficiency power unit

- Power Pack sizes up to 150HP (dual-motor units available)

- Lockable main circuit breaker prevents unauthorized machine activation

- Low oil shutdown switch, high oil temperature shutdown switch, and oil shut-off valve protects your valuable machine

- Quiet-running pump system

- Electrically actuated regen hydraulic system

- Hydraulic pressure transducers are standard for the most accurate hydraulic pressure readings

- Air-to-oil cooler

- 150- to 600-gallon hydraulic oil reservoir

Wire positioners are on the twister cabinet side for precise twister alignment and wire pick-ups.

Wear resistant, replaceable liners on ram slides, 500 Brinell steel liners on floor & ram bottom. Oversized ram hold-down bars are adjustable from the exterior of the machine.

The Totally Enclosed Fan Cooled (TEFC) motor features a quiet-running pump system.

Serrated body and ram bolt-in shear blades are shimmable and replaceable (not available in the PC-Series and WC models).