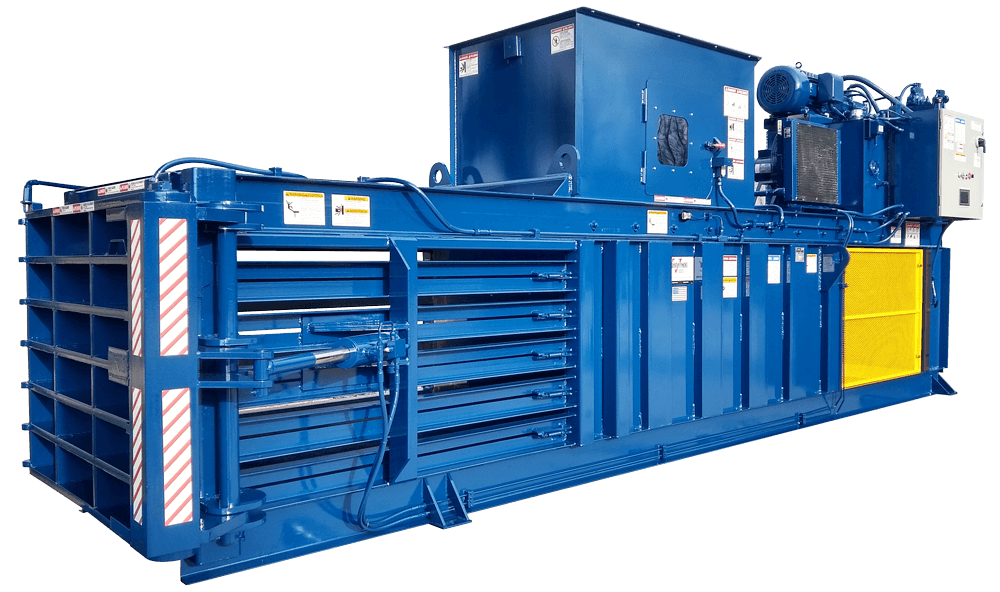

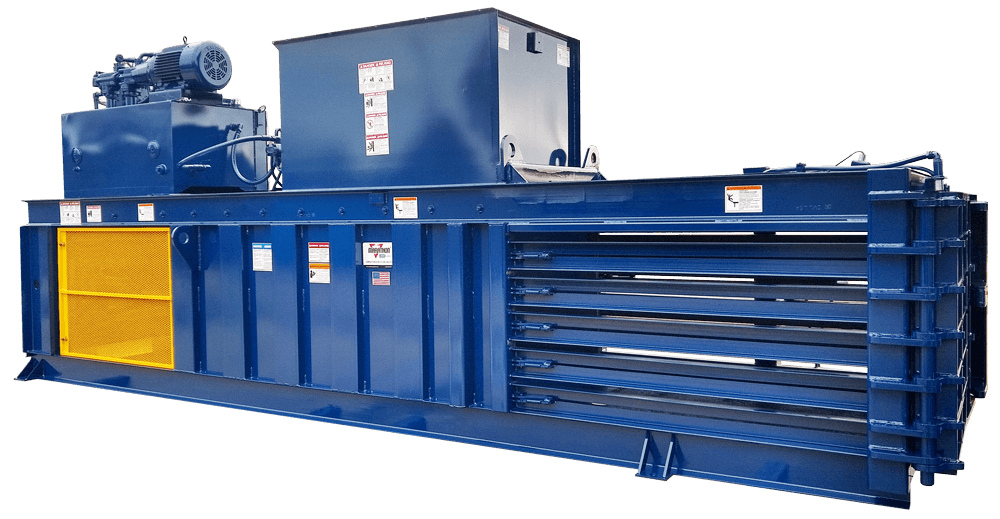

Closed-End Manual-Tie horizontal Cardboard recycling Balers

Marathon® Closed-End Horizontal Cardboard Recycling Balers are mid-sized balers that process a wide variety of material and can produce up to 20 tons of Old Corrugated Cardboard (OCC) in a typical shift.

Our Closed-End Manual-Tie Horizontal Cardboard Balers are available with a wide array of options and can be configured for virtually any cardboard OCC recycling facility application.

Have Questions About Closed-End Manual-Tie Recycling BALERS?

Contact your local Marathon Recycling Compaction team today to request a complimentary site survey.

5 Yr. Structure | 1 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Transfer Compaction & Recycling Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. The existing Marathon Recycling Solutions Warranty has also been updated to include Transfer Compactors. The Transfer Compactor and Recycling Solutions Warranty include 5-years structural warranty, 1-years part warranty, and 1-year labor warranty.Closed-End Horizontal Baler Features

- Wide variety of feed openings available to accommodate your specific material size

- Compatible with conveyor, chute, cart dumper, or hand-feed applications

- Standard photocell feature enables automatic cycling

- Standard touchscreen controls, hydraulic door latch, and rotary bale-length gauge facilitate easy operation

closed-end horizontal baler standard Features

Conveyor, chute, or hand-feed hopper

Compatible with conveyor, chute, cart dumper, or hand-feed applications

Standard photoelectric cell enables automatic cycling

Standard touchscreen controls, hydraulic door latch, and rotary bale-length gauge facilitate easy operation

Rotary bale-length gauge activates the bale made light automatically, with no flag pole to engage or disengage

Reversible and replaceable ram-shear blade and serrated body-shear blade

Heavy-duty power pack with 20 or 30 HP (Totally Enclosed Fan-Cooled) TEFC motor

Audio/visual start-up alarm

Center position valve, 10-micron return-line filter, and 100 mesh suction-line strainer

High-efficiency power unit and electrical disconnect are standard on all Marathon Closed-End Horizontal Balers.

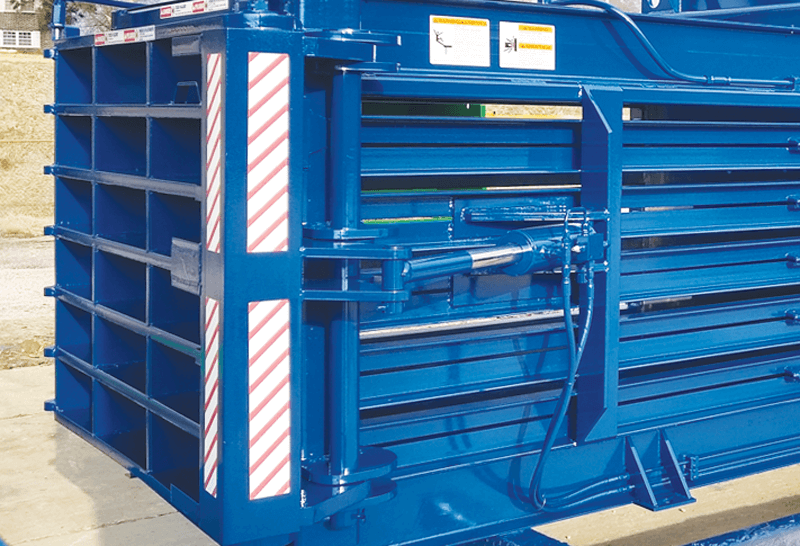

Hydraulic Door Latch

Marathon Closed-End Balers feature a hydraulic door latch, standard on all models.

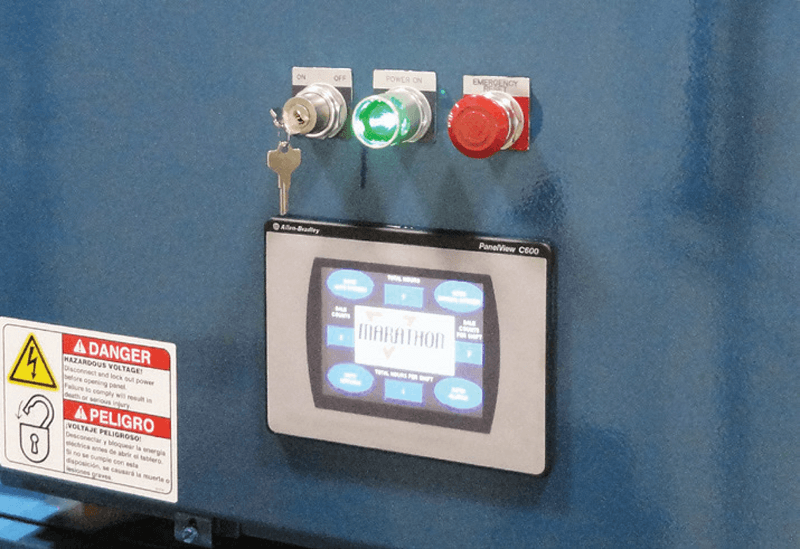

Touchscreen Controls

The touchscreen enables full automatic and manual control with one touch. Screens may be customized, password protected, and are designed with alarm, diagnostic, and help screens.

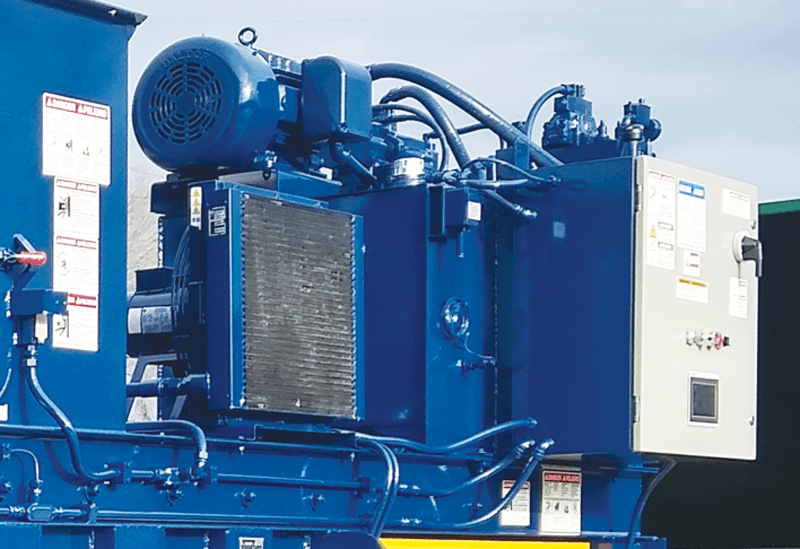

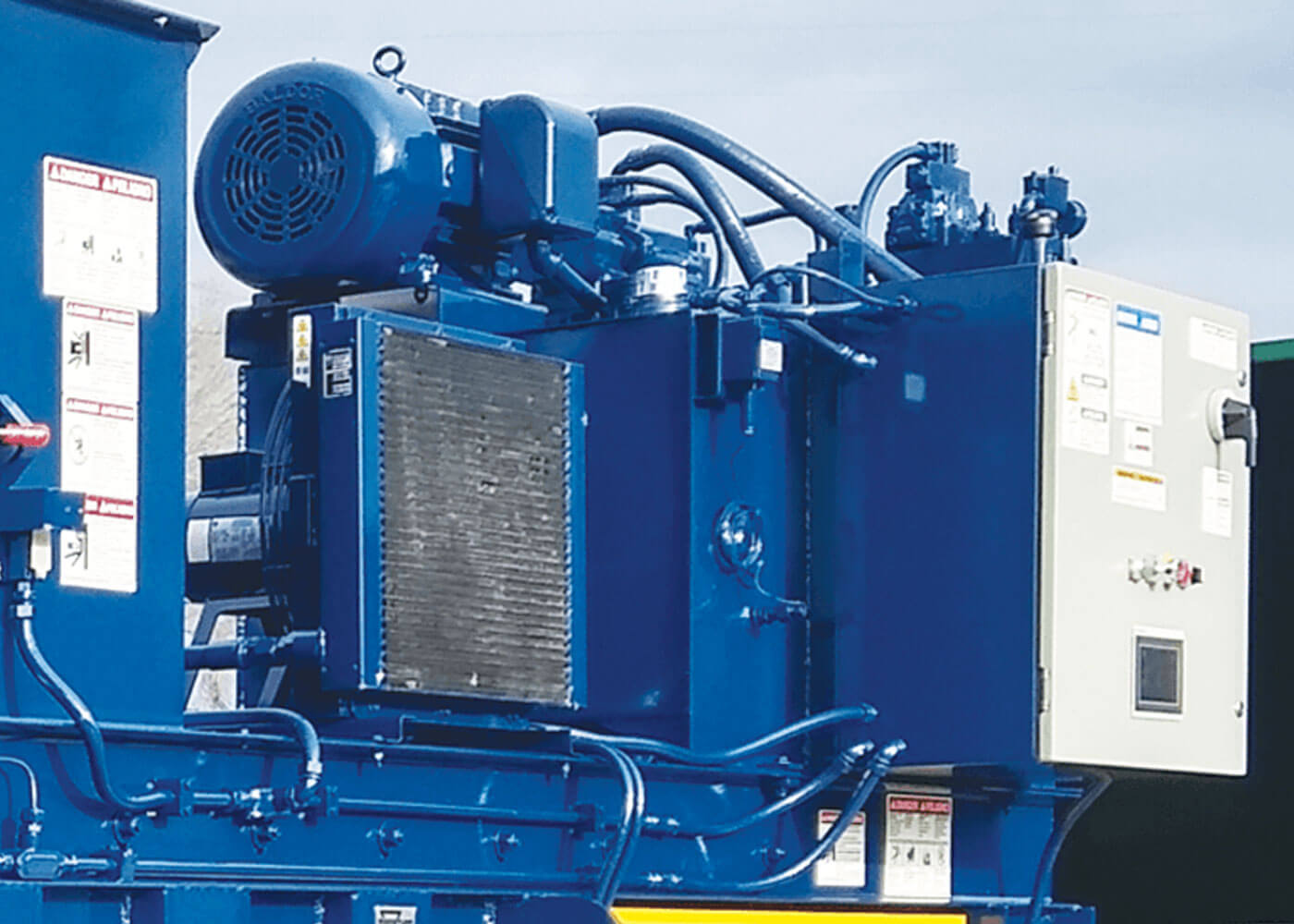

High-Efficiency Power Unit

High-efficiency power unit and electrical disconnect are standard on all Marathon Closed-End Horizontal Balers.