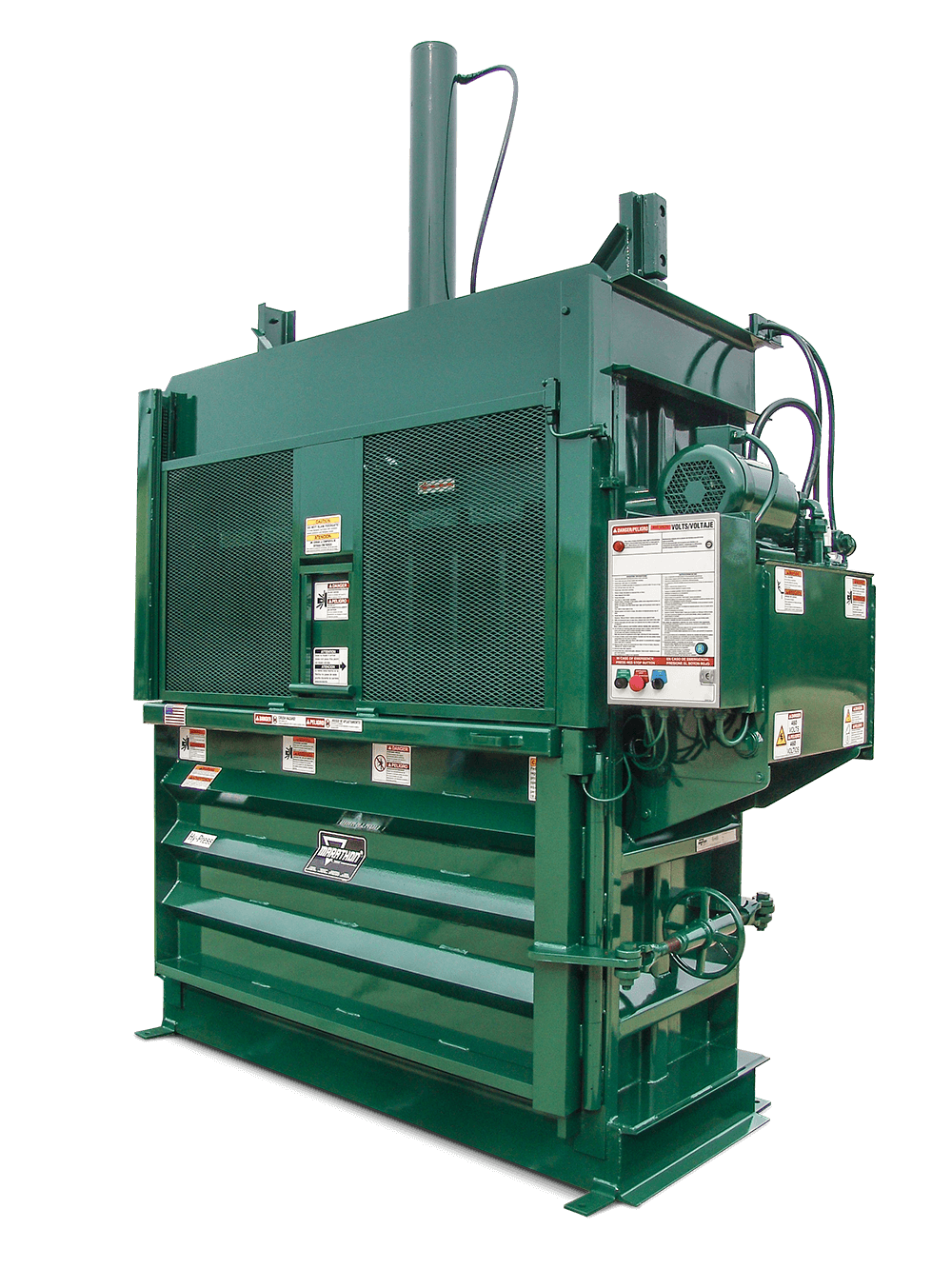

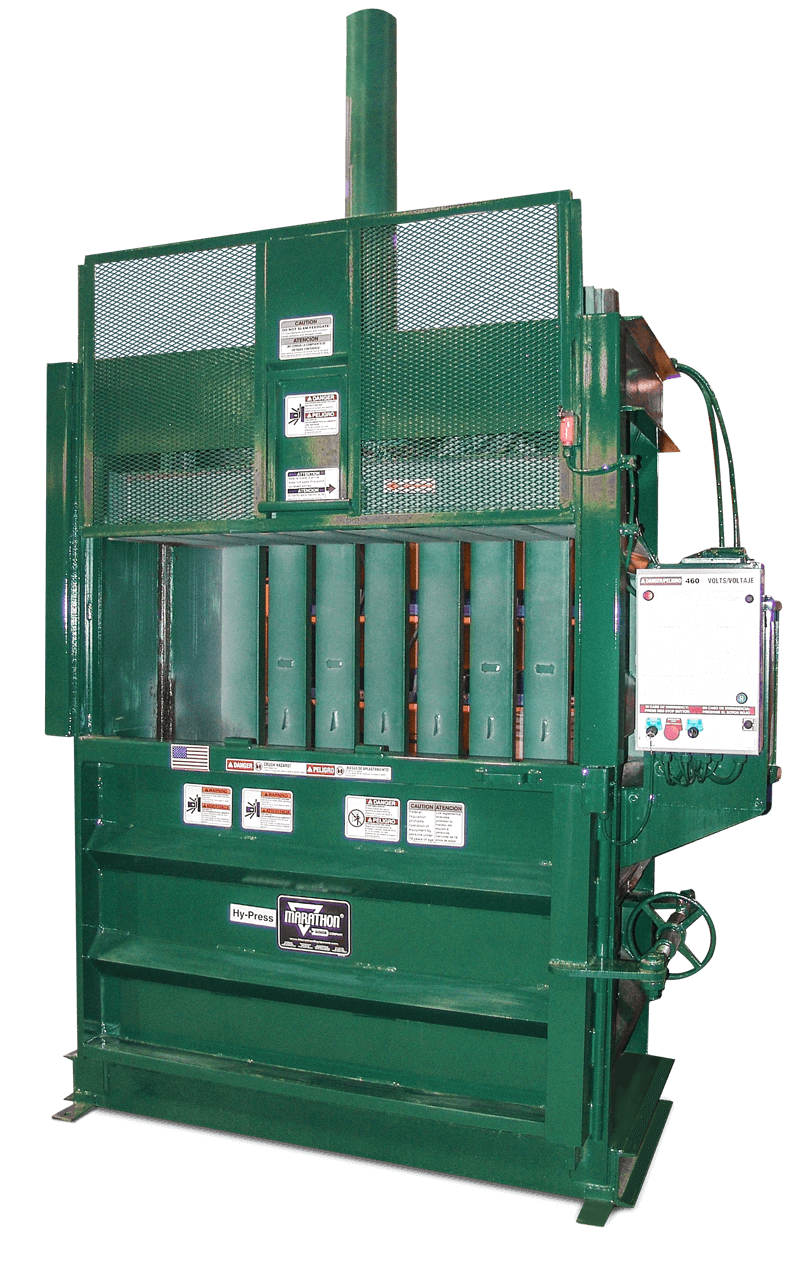

V-6030 HD Heavy-Duty Vertical Cardboard Balers

Innovative, Simple cardboard baling and Recycling solutions.

Marathon® Vertical Cardboard Balers set the recycling industry standard for quality baling and recycling equipment. Marathon cardboard balers feature many innovations for ease-of-use and maintenance-friendly access. Features such as the side-mounted power unit, front-facing panel box, and redundant feed-gate interlock system, all add up to a reliable cardboard baler for years of trouble-free cardboard and paper bale recycling.

Have Questions About Heavy-Duty Vertical Cardboard Balers for Recycling?

Contact your local Marathon Cardboard baler expert team today to request a complimentary site survey.

3 Yr. Structure | 2 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Compaction Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. Our existing Signature Series® Warranty, Compactor Warranty, and Auger Warranties have been combined into a new Compaction Solutions Warranty. The Compaction Solutions Warranty includes 3-year structural warranty, 2-year part warranty, and 1-year labor warranty.V-6030 HD Vertical Cardboard Baler Features & benefits

- Easy to use

- Maintenance-friendly

- Cardboard bale weights of up to 1,100 lbs.

- Side-mounted hydraulic power unit

- Front-facing panel box

- Redundant feed-gate interlock

- Customizable with many options

- Fixed retainer teeth on the door and rear of the baler reduce material springback.

V-6030 HD Heavy-Duty Vertical Cardboard Baler standard features

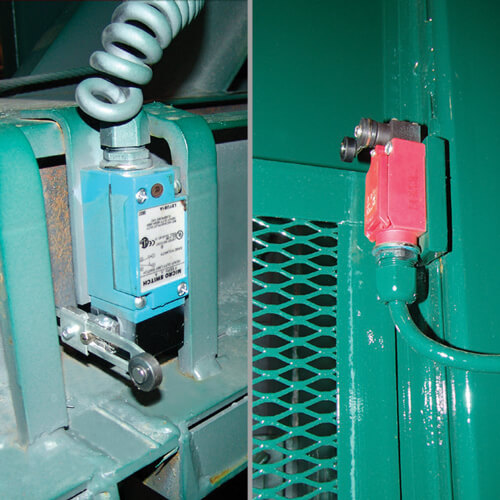

Marathon vertical cardboard recycling balers feature a redundant interlock system, incorporated into the feed-gate switch.

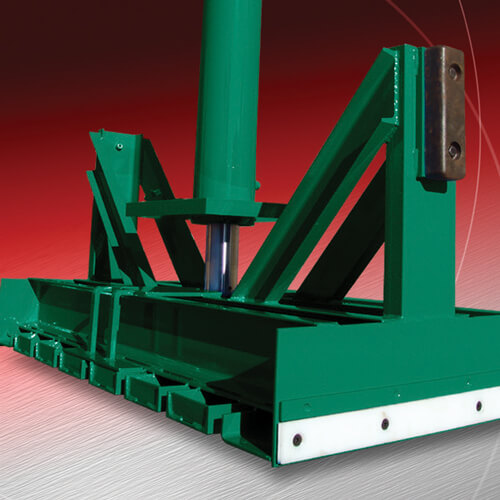

Marathon vertical cardboard recycling balers feature Platen replaceable high-density polyethylene guides to absorb side thrust, as well as replaceable cast iron shoes.

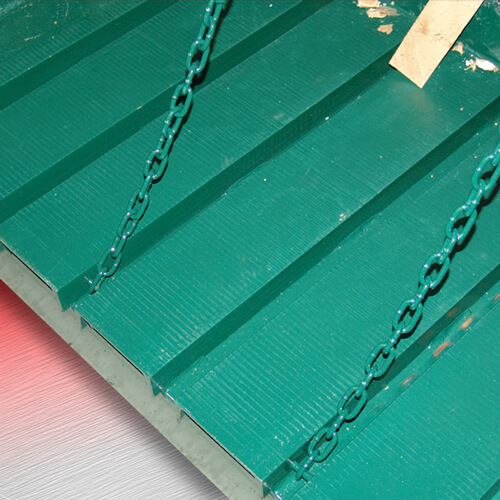

Marathon vertical cardboard balers/ standard chain bale ejector is manually set after the bale door is opened.

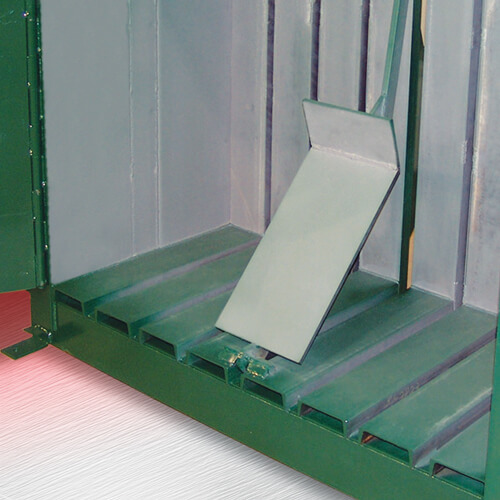

Our vertical cardboard balers feature an optional automatic bale. Cardboard bales and automatically ejected from the baler when the bale door is opened.

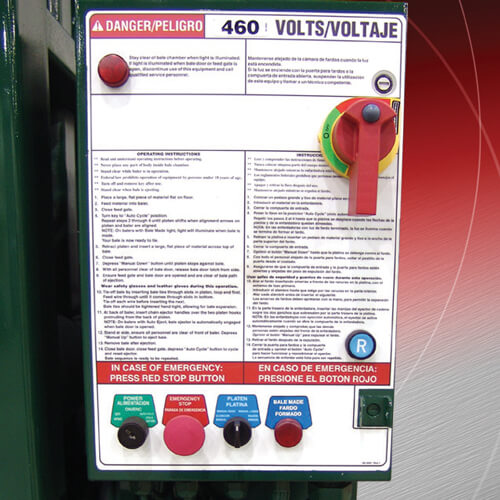

All Marathon Cardboard Balers feature standard controls: Key Lock On/Off Auto Cycle, Emergency Stop, and Platen Raise/Lower. Baler Ready light indicates the unit is operational. Shown with optional “Bale Made” light and electrical disconnect.

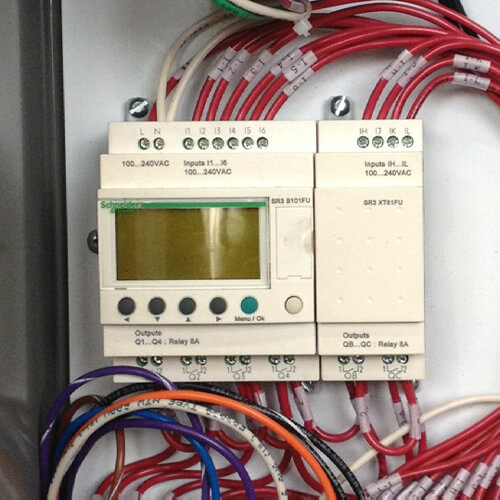

Marathon cardboard recycling balers feature a panel box with programmable “smart” relay control system, that disables the baler if there is an attempt to override the interlocks. It also adds diagnostic and trouble-shooting capabilities.

When operating our cardboard balers, an automatic feed-gate opens at the end of each bale cycle as the platen is retracted.

The Marathon vertical cardboard baler’s side-mounted, self-contained power unit is convenient for maintenance and servicing. The front opening control panel eliminates the need for 48″ baler side clearance as required by NEC standards.

Marathon cardboard balers have an optional “Bale Made” light alerting the operator of successful bale creation.

Marathon vertical cardboard recycling balers have an optional Electrical Disconnect Switch for optional safety when serving the baler.

For additional performance, Marathon vertical cardboard recycling balers are available with an Oil Heater for improved speed and function in colder climates.

Marathon cardboard balers are equipped with a Single-Phase Power Unit for standard installations.

Marathon vertical cardboard balers are equipped with a convenient Front bale Tie-Off System for simple tying of cardboard bales.

Marathon vertical cardboard balers Optional Wire Guides simplify the process of creating cardboard bales.

Marathon vertical cardboard recycling balers are equipped with Lockable Disconnect for increased safety.

MARATHON VERTICAL CARDBOARD BALERS

Features for Virtually Any Application

Marathon vertical cardboard balers and paper balers can also be equipped with optional features that add even more efficiency and ease-of-use. An automatic cardboard bale ejector that activates when the bale door is opened is available. The ejector does not extend beyond the wire guides, enabling the unit to be placed directly against a wall. Wire guides eliminate the need to go behind the baler, allowing for a complete front tie-off to be performed in front of the unit. The optional “Bale Made” light illuminates when a bale is made, notifying the operator when the bale is ready for ejection. A lockable electrical disconnect can be added for local Lock-Out/Tag-Out. Learn why Marathon Cardboard Balers are the preferred solution for cardboard and paper recycling.

Redundant Interlock System

A redundant interlock system is incorporated into the cardboard baler feed-gate switch.

Platen Features

Platen features replaceable high-density polyethylene guides to absorb cardboard bale side thrust, as well as replaceable cast iron shoes.

Chain Ejector

The standard chain cardboard bale ejector is manually set after the bale door is opened.

Optional Bale Ejector

An optional automatic cardboard bale ejector is also available. It is actuated when the bale door is opened.

Control Options

Standard controls: Key Lock On/Off Auto Cycle, Emergency Stop, and Platen Raise/Lower. Baler Ready light indicates the unit is operational. Shown with optional “Bale Made” light and electrical disconnect.

Smart Control System

Panel box features a programmable “smart” relay control system that disables the cardboard baler if there is an attempt to override the interlocks. It also adds diagnostic and trouble-shooting capabilities.

Automatic Feed Gate

An automatic cardboard baler feed-gate opens at the end of each cycle as the platen is retracted.

Side-Mount Power Unit

The cardboard baler side-mounted, self-contained power unit is convenient for maintenance and servicing. Front opening control panel eliminates the need for 48″ side clearance as required by NEC standards.

V-6030 HD Heavy-Duty Vertical Cardboard Baler Resources

Have Questions About Heavy Duty Vertical Cardboard Balers for Recycling?

Contact your local Marathon Cardboard Baler team today to request a complimentary site survey.

Frequently Asked Questions About Marathon Cardboard Balers

A cardboard baler is a machine that compresses cardboard waste into compact, manageable cardboard bales for easier handling, storage, and transportation. Marathon Equipment cardboard balers work by using powerful hydraulic systems to compress cardboard and other paper products, and then bind it into compact cardboard bales, which can be easily recycled or sold.

The cost of a cardboard baler can vary widely based on its size, capacity, and the specific features it includes. Generally, smaller, manual-tie balers are less expensive, while larger, automatic-tie balers require more of an initial investment, but yield significant returns through increased performance and productivity, resulting in greater profit from the sale of cardboard balers. Marathon Equipment offers a wide range of cardboard balers at various price points, that are an unbeatable value for different business needs and budgets.

Using a cardboard baler in waste management and recycling has several benefits. First, cardboard balers reduce the physical space needed for storing waste cardboard and paper. Second, cardboard balers can save businesses money on waste removal costs. Third, cardboard balers promotes sustainability by making cardboard and paper materials easier to recycle. Fourth, balers can generate revenue if the baled cardboard or paper is sold. Marathon Equipment cardboard balers are designed to maximize these benefits and more.

The space required to operate a cardboard baler depends on the size of the baler and the volume of cardboard or paper you plan to process. Marathon Equipment offers a large variety of cardboard baler sizes to suit different spaces, from small vertical balers that can fit in a corner, to larger horizontal balers that require more space.

The line of Marathon Equipment balers include:

The amount of cardboard a baler can compact depends on the model and size of the baler. Smaller cardboard balers might compact a few hundred pounds of cardboard per bale, while larger models can compact over a thousand pounds into a single bale. Marathon Equipment’s range of cardboard balers offers a variety of compaction capacities to suit different needs.

A cardboard baler can save businesses money in several ways. By compacting cardboard waste, it reduces the volume of waste, which can lower disposal costs. Additionally, the cardboard bales produced can often be sold for recycling, generating additional income. Marathon Equipment’s cardboard balers are designed to be efficient and effective, maximizing potential savings.

Regular maintenance is essential for the longevity and safety of a cardboard baler. This might include routine inspections, cleaning, and hydraulic oil checks. The frequency of maintenance can depend on the model and how often the cardboard baler is used, but a general guideline is to perform a thorough check every few months. Marathon Equipment provides detailed maintenance guidelines for all of our cardboard balers.

Most types of cardboard can be baled, including corrugated cardboard, cardboard boxes, and cardboard packaging materials, and waste paper products. Marathon Equipment’s cardboard balers are designed to handle a wide variety of cardboard types, making them the most versatile choice for businesses.

Operating a cardboard baler safely involves following the manufacturer’s instructions, using safety gear, and ensuring that only trained personnel operate the machine. Safety features such as emergency stop buttons and safety interlocks are standard in Marathon Equipment’s cardboard balers to ensure safe operation.

Baled cardboard can often be sold to recycling companies or waste management firms, which then process the cardboard bales for reuse. Cardboard bale prices can fluctuate based on market demand and the quality of the baled cardboard. Marathon Equipment cardboard balers are extremely efficient and often can allow for the greatest total revenue for the sales of cardboard-bales.

Cardboard balers are used in a wide range of industries that generate significant amounts of cardboard waste. Here are a few examples:

- Retail Industry: Stores, especially large supermarkets and department stores, generate large amounts of cardboard waste from product packaging. Cardboard balers can help manage this waste effectively and potentially generate additional revenue.

- Manufacturing: Many manufacturing firms use cardboard in their packaging or receive goods packaged in cardboard. Balers can help these businesses manage their waste stream and promote sustainability.

- Warehousing and Distribution: These businesses handle large volumes of goods, often packed in cardboard, and a baler can help manage the resulting waste.

- Hospitality: Hotels and restaurants often have significant cardboard waste from supplies and food deliveries. Cardboard balers can help keep waste areas clean and manageable.

- Waste Management and Recycling: These industries use cardboard balers extensively to compact collected cardboard for efficient transport and to prepare it for the recycling process.

Marathon Equipment cardboard balers are versatile and robust, making them suitable for all these industries and more. They offer a range of models to suit different volumes of waste and different business needs.

See specific benefits of cardboard balers for the following industries:

- Cardboard balers for schools, colleges, and education facilities

- Cardboard balers for thrift Stores

- Cardboard balers for senior care, retirement homes

- Cardboard balers for convenience stores

- Cardboard balers for logistics, distribution centers, trucking companies

- Cardboard balers for apartment buildings & residential applications

- Cardboard balers for malls/retail stores

- Cardboard balers for mixed commercial/residential use

- Cardboard balers for restaurants

- Cardboard balers for auto / car dealers

- Cardboard balers for grocery stores

- Cardboard balers for big box stores

- Cardboard balers for theme parks

- Cardboard balers for industrial / manufacturing

- Cardboard balers for hospitals and institutions

- Cardboard balers for hotels

- Cardboard balers for transfer stations / Municipal

Marathon Equipment cardboard balers offer a wide range of capacities, depending on the model. They can process anywhere from a few hundred pounds to over a thousand pounds of cardboard per hour. Specific capacities depend on the model and the type and density of the cardboard being baled.

Marathon Equipment puts a strong emphasis on safety for all of our balers and compaction equipment. Our cardboard balers are designed with various safety features including to ensure the operator’s safety. As with all baling equipment and machinery, it is very important to always follow manufacturer’s safety instructions and properly train all operators prior to use.

Marathon Equipment cardboard balers, are instrumental in recycling initiatives. By compacting and bundling cardboard waste, these balers reduce the need for landfill space, encourage recycling, and can even generate revenue for businesses through the sale of baled cardboard.

Regular maintenance of a cardboard baler is essential for optimal performance and longevity. This includes regular checks and replacement of hydraulic oil, regular inspections for wear and tear, and keeping the machine clean. Marathon Equipment offers comprehensive maintenance guides and support for all of our cardboard recycling balers.

Yes, Marathon Equipment offers comprehensive installation and setup services for all of our cardboard balers. Their team of experienced professionals will ensure that your baler is set up correctly and safely, and that your team is trained in its operation and maintenance.

While primarily designed for cardboard, many of Marathon Equipment’s balers can also process other recyclable materials such as paper, plastic, and aluminum. Always check the specifications of your model before processing other materials.

With proper maintenance and care, Marathon Equipment cardboard balers can last for many years. The lifespan of a cardboard baler depends on several factors, including how often it’s used, the volume of material processed, and adherence to maintenance schedules. In addition, Marathon Equipment’s Certified Remanufactured program allows users to trade in their cardboard baler on OEM Remanufactured balers, which feature unbeatable values – with the same warranty as a new baler.

Choosing the right cardboard baler depends on several factors including the volume of cardboard waste you generate, the space you have available, your budget, and your desired level of automation. Marathon Equipment offers a range of cardboard recycling balers to suit different needs, and their team of experts can help guide you to the best choice for your business.

Not sure what cardboard baler or compactor you need? View our helpful Product Finder to find the perfect equipment for your specific needs.