drc-ii dual-Compartment Self-Contained recycling compactor

The DRC II Dual-Compartment Self-Contained Recycling Compactor is one dual-purpose compactor, occupying one space, with two separate compartments that enable you to compact a wide range of waste and recyclables all at one time.

Maximize your recycling processing with the Marathon® DRC-II Dual-Compartment Self-Contained Recycling Compactor!

Have Questions About The Drc II Trash Compactor?

Contact your local Marathon Compaction team today to request a complimentary site survey.

3 Yr. Structure | 2 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Compaction Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. Our existing Signature Series® Warranty, Compactor Warranty, and Auger Warranties have been combined into a new Compaction Solutions Warranty. The Compaction Solutions Warranty includes 3-year structural warranty, 2-year part warranty, and 1-year labor warranty.DRC-II Dual-Recycling Compactor Features

- Two compartments segregate waste and recyclables, increasing your return on the sales of recycled materials

- Two compactors in one

- Neat and attractive appearance

- Excellent for applications where recycling is required but there is only room for one compactor

Two compartments segregate waste and recyclables, increasing your return on the sales of recycled materials

Garbage and corrugated, corrugated and high-grade paper, paper and aluminum cans, garbage and co-mingled recyclables

Two separate compartments segregate waste and recyclables, which increases your return on the sale of recycled materials.

Separate, compact, and process two different materials, such as recyclables and garbage, at the same time in an area where space permits only one compactor.

Both recyclables and garbage are neatly contained after compaction, providing your building, facility, mall, or store

with a neat and attractive appearance.

Excellent for applications where recycling is required but there is only room for one compactor

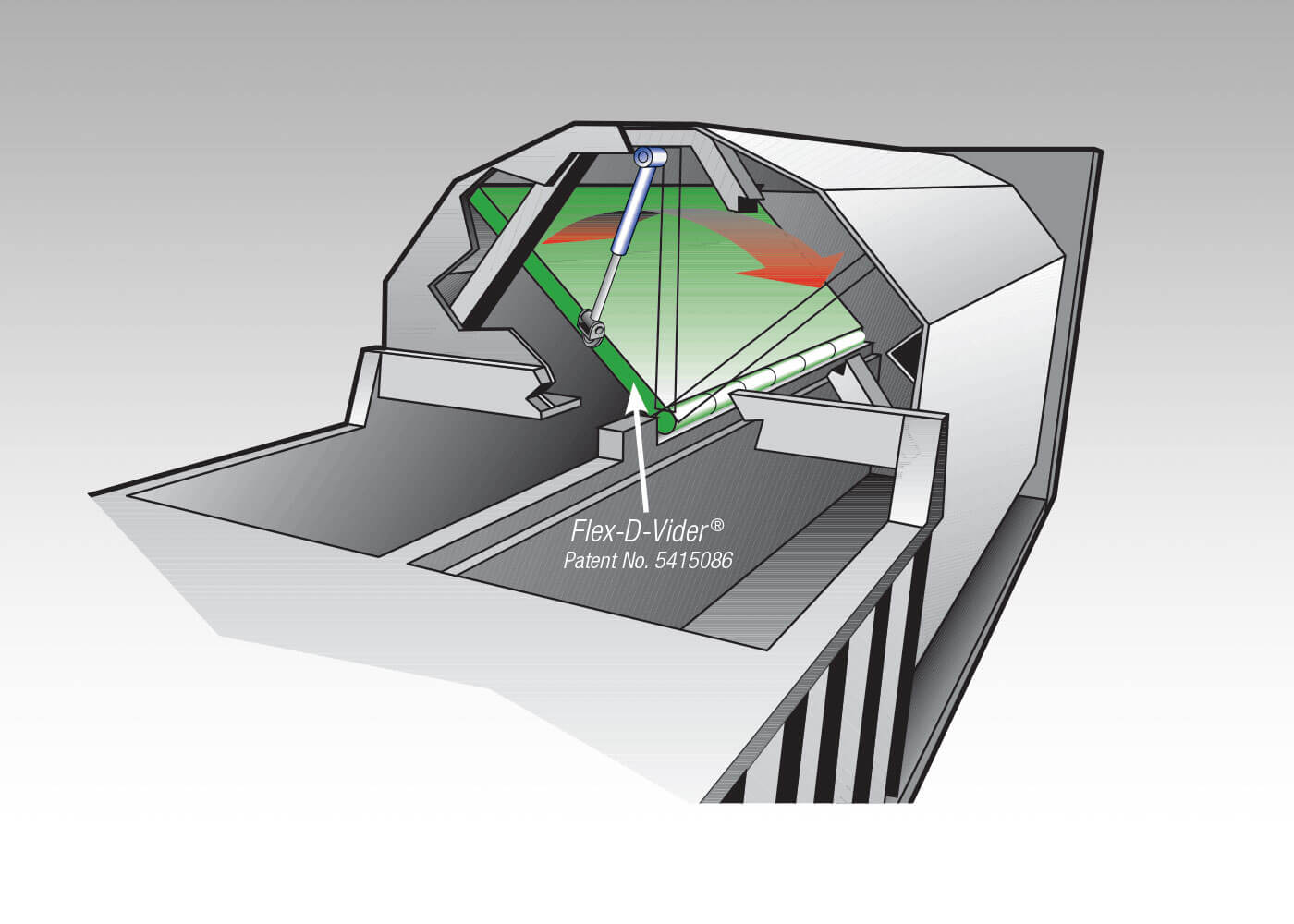

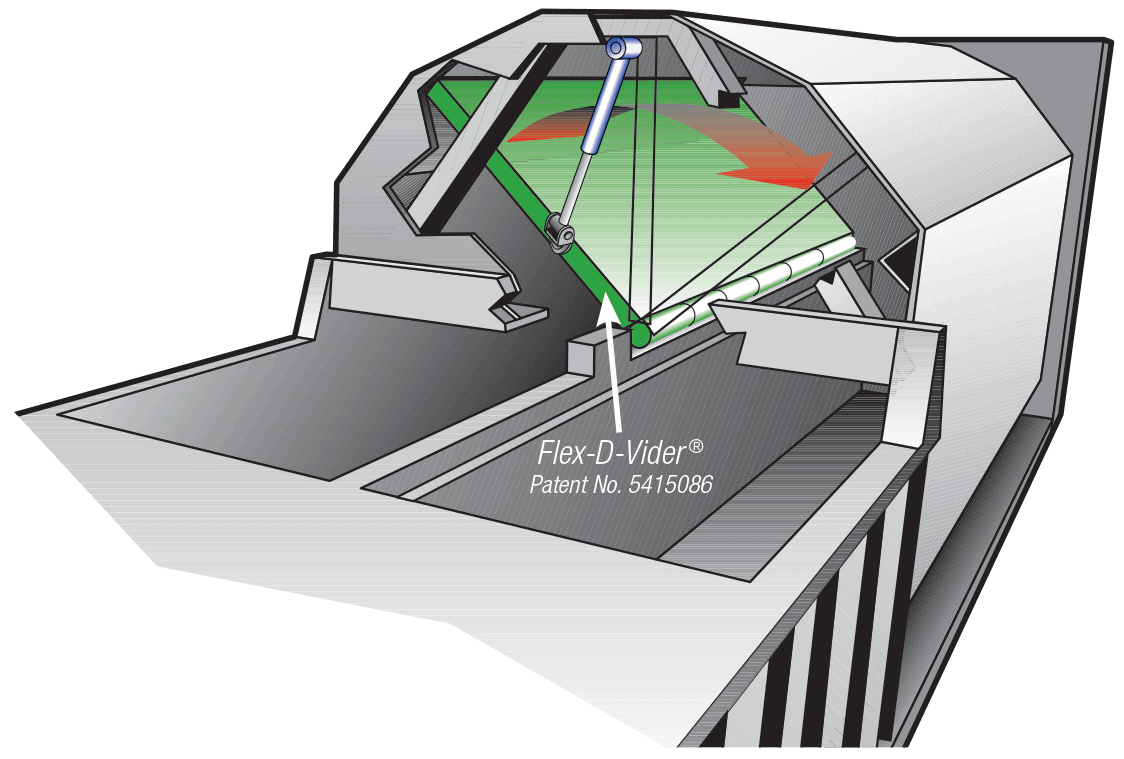

Marathon Flex-D-Vider

Creates Two Variable-Capacity Compartments

The DRC II has a total capacity of 28 cubic yards. The two variable-capacity compartments are separated by a 24″ high, solid-welded barrier. This barrier wall prevents liquid from leaking from one side to the other.

The DRC II accepts and compacts unequal and unpredictable volumes of two separate discardables. This is made possible by the patented Marathon Flex-D-Vider®, a pivoting steel wall that adjusts the compartments’ capacities during the loading and packing process. For easier discharge of the materials in the smaller compartment, a hydraulic cylinder enables the operator to move the Marathon Flex-D-Vider to the vertical center of the container, relieving the pressure on the remaining waste or recyclables. Each compartment when loaded, can represent as little as 30% or as much as 70% of the unit’s total volume. The DRC II can also be chute-fed to increase customer security and reduce labor costs.

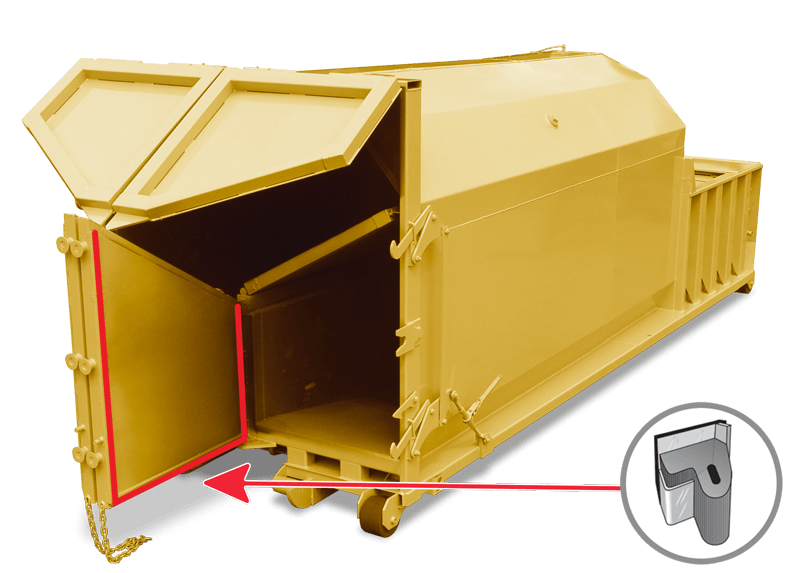

Four Individual Doors for Controlled Discharge of Compacted Material

Due to the many variable positions in which the Marathon Flex-D-Vider can be located, four individual doors are used for the discharge of materials.

- Upper doors are top-hinged and have ratchet locks that enable the door to be opened independently of the lower doors.

- Lower doors are hinged in the center of the container. Each door is equipped with the standard ratchet latch and opens independently for controlled discharge of compacted material.

P-Seal Watertight Closure

For wet waste applications, an optional door gasket is available with the custom designed Marathon P-shaped door seal, developed specifically for self-contained compactors used for wet waste. Either or both sides may be gasketed.

DRC II Dual-Recycling Compactor Features & Options

Remote Power Pack

Separate from the compactor/container, the Marathon brand Remote Power Pack remains free of damage caused while hauling to and from disposal sites, and stays free of problems caused by landfill dust. There are no electrical connections to make or break, and two simple-to-use, hydraulic quick disconnects couple the power unit to the packing head. All Marathon Remote Power Packs are built in-house to our quality standards, and each unit must pass a series of stringent tests before it can be shipped with the selected compactor.

Optional Doghouse and Chute

The Dual-Recycling Compactor can be fitted with a variety of optional equipment such as through-the-wall security chutes and lockable doghouse hoppers. The DRC II is well suited for ground, doghouse, dock, or chute feed applications. Doghouses may be rear- or side-feed, or both.

AVAILABLE WITH BAYNE THINLINE CART LIFTER

Equipped with an integral cart lifter, the DRC-II offers an economical and safety-conscious solution for a wide variety of waste material handling applications.

Bayne® Thinline® cart lifters work with standard two-bar roll-out carts and can lift up to 750 lbs. Lifters have a durable, powder-coated finish that can stand up to the elements.

PERFECT FOR TIPPER-SYSTEM APPLICATIONS

The DRC-II is the perfect choice for applications requiring a tipper system. These tippers can extend the benefits of compaction to all areas of operation while keeping equipment investments to a minimum. Carts or containers can be located at individual waste generation sites within the operation, and then emptied into the compactor with the cart-tipper option.